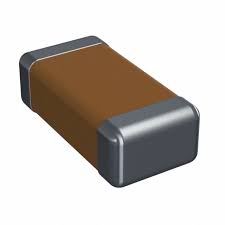

The rapid evolution of medical technology demands high-performance components to ensure the reliability and efficacy of life-saving devices. Among these components, capacitors play an important role in managing power supply, signal processing, and energy storage.

Recent advancements in medical-grade capacitor technology have improved the performance and reliability of medical devices, meeting the strict requirements of industries such as medical, military, space, avionics, and industrial sectors.

The Need for High Reliability

Capacitors are integral to various medical devices, ranging from diagnostic equipment like MRI machines and CT scanners to implantable devices such as pacemakers and defibrillators.

Medical devices, especially those implanted in the body or used in critical care, must operate without fail. Unlike consumer electronics that can be easily recharged or repaired, the failure of a capacitor in a medical device can have serious consequences. Recent advancements in medical-grade capacitors have been aimed at boosting their reliability by focusing on several key areas:

Miniaturization and High Capacitance Density

As medical devices become smaller and more portable, there’s a growing demand for capacitors that offer high capacitance in a compact form. Advances in materials science and manufacturing techniques have made it possible to develop capacitors with higher capacitance densities. These miniaturized capacitors are particularly suited for implantable devices and portable diagnostic equipment where space is limited.

Better Materials

Advances in dielectric materials—the insulating layer within capacitors—have led to higher energy density and improved temperature performance. This means smaller capacitors can now handle more power, which is especially important for the design of compact medical devices. Additionally, improvements in electrode materials have resulted in better conductivity and greater reliability.

Reducing Leakage Current

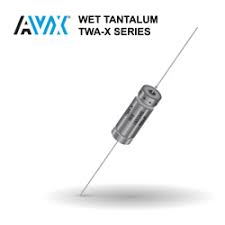

Leakage current is the small amount of current that can escape from a capacitor, potentially draining batteries or damaging sensitive medical equipment. New capacitor technologies, including wet tantalum capacitors and supercapacitors, have made strides in reducing leakage current, assuring that devices operate efficiently and without unintended power loss.

Improved Reliability and Longevity

Reliability is a top priority in medical applications, where devices must consistently perform over extended periods. Advanced capacitors are now designed with superior dielectric materials, offering greater reliability and longer operational lifespans. This reduces the need for frequent replacements, keeping medical devices safe and operational for years.

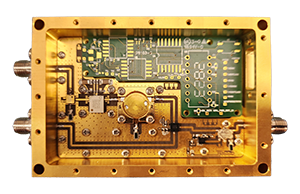

High Voltage Capacitors for Advanced Medical Equipment

Certain medical devices, such as defibrillators and advanced imaging equipment, require capacitors that can handle high voltages without degrading over time. The latest high-voltage capacitors are engineered to meet these demanding requirements, providing reliable performance in necessary applications.

Biocompatibility

The materials used must not cause adverse reactions for devices implanted in the body. New advancements in materials and manufacturing techniques have improved the biocompatibility of capacitors, reducing the risk of rejection or inflammation.

Long-Term Performance

Medical devices are designed to last for years, and their components must be just as durable. Recent capacitor designs focus on solid construction and thorough testing to ensure they will perform reliably over the long term, meeting the demanding expectations of the medical field.

With advancements in materials and design, our team at Techni-Source Corporation delivers capacitors that meet the demands of the medical field. We remain a trusted partner for companies in Arizona, New Mexico, Las Vegas, NV, and El Paso, TX, helping them succeed in their respective industries. Contact us today to learn more!