Electromagnetic interference (EMI) shielding is commonly used to protect electrical components from electrically dominant waves. However, there are instances where components need to be shielded from magnetically dominant waves. In such cases, magnetic shields play a crucial role.

Keep reading to learn more about the best practices for magnetic shielding design.

Types of Magnetic Shields

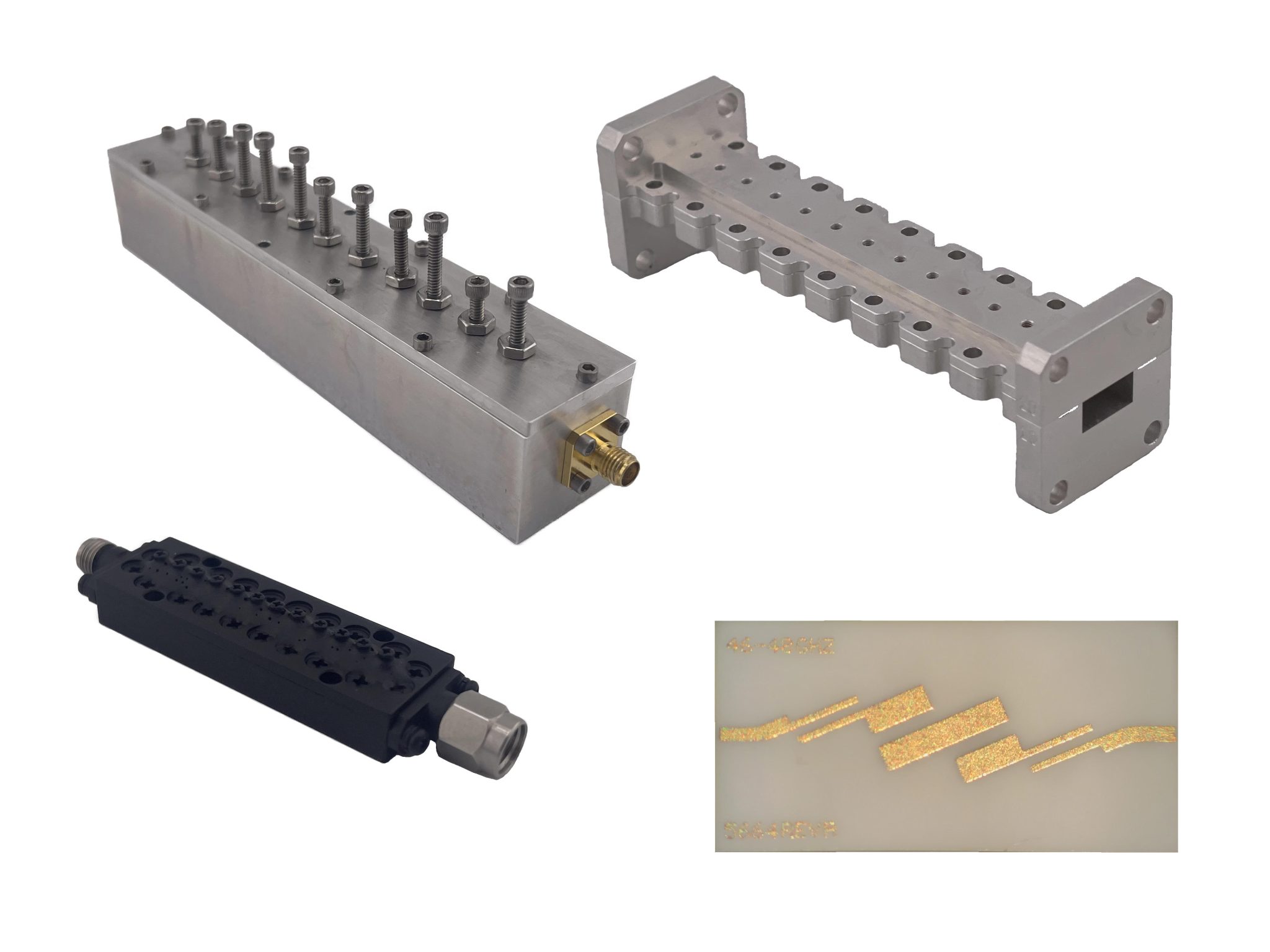

Electromagnetic waves consist of electric fields (E-fields) and magnetic fields (H-fields). Magnetic shields protect components from magnetically dominant waves. There are two types of magnetic shields: lossy shields and flux-entrapment shields. Lossy shields are used at high frequencies when both E-fields and H-fields are present. Flux-entrapment shields surround the protected area and divert the magnetic flux lines, preventing them from entering the shielded space.

What Is Coplanarity?

Coplanarity, also known as flatness, is a measure of how close a surface is to a perfect 2D plane. It is an important factor in the design of board-level shielding, as it affects the performance of EMI/RF shields. Proper coplanarity minimizes the risk of EMI/RF interference by creating a tight seal and preventing electromagnetic waves from leaking into or out of the shielded space.

Factors Affecting Complanarity

Several factors can influence the coplanarity of magnetic shields, including shape, size, manufacturing method, handling, and packaging. Let’s look at each a little more closely:

Shape

The design of the shield directly affects its coplanarity. Rectangular shields, which have four surfaces touching the circuit board, have a coplanarity defined by the distance between those surfaces and the board. More complex shield shapes can increase the number of surfaces and, consequently, the coplanarity.

Size

The size of the shield also affects coplanarity. Larger shields generally have larger coplanarities due to their increased surface area.

Manufacturing Method

The method used to manufacture the shield impacts its coplanarity. Traditional methods involve cutting the blank and forming the walls one at a time, which may result in slight variations and affect the flatness of the shield. Forming multiple walls simultaneously can reduce coplanarity by improving tolerance stack-up.

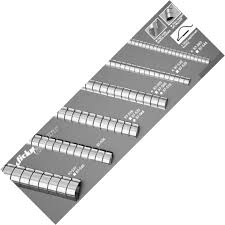

Handling and Packaging

Using protective measures such as trays, tape, and reel packaging can help maintain the shield’s manufactured coplanarity.

Tips for Ensuring Corrosion Resistance

In environments with high humidity or exposure to moisture, it is essential to make EMI shielding products corrosion-resistant to maintain their performance. Here are a few tips to protect equipment from corrosion:

Surface Treatment

Apply paint or a plate to your electronic enclosures to prevent corrosion, oxidation, rusting, and tarnishing. Use corrosion-resistant and electrically conductive materials for maximum shielding efficiency. Additional coatings can provide protection in high-humidity environments.

Quality EMI Gaskets

Select gasket materials that minimize the variation in electrochemical potential relative to the metal structure. Elastomeric gaskets with filler particles can provide both corrosion resistance and EMI shielding. Opt for silver-plated copper, pure silver, or silver-plated aluminum fillers for corrosion-resistant EMI protection.

Opt for Additional Moisture Sealing

Use secondary moisture sealing methods to prevent corrosion caused by electrolytes. In aircraft applications, a seal-to-seal design can effectively prevent water seepage.

Getting What You Need

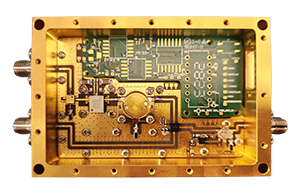

Designing magnetic shields for effective shielding requires attention to detail, particularly in terms of coplanarity and corrosion resistance. If you are looking for EMI/RFI shielding products, look no further than those from Leader Tech.

At Techni-Source Corporation, we are proud to be responsible for the sale of Leader Tech products. Contact us today if you would like a consultation on which shielding product would best suit your needs.